Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

The Dynamic World of Electronic Components Manufacturing Sales

In the world of modern technology, electronic components play an indispensable role in making everything from smartphones to electric cars run efficiently. Behind every advanced gadget or high-tech product, there are intricate parts that allow these devices to function seamlessly. These parts are what we call electronic components. The process of making these components and their subsequent sales is an industry that continues to grow and evolve at an impressive pace.

In this blog post, we will dive deep into the world of electronic components manufacturing sales, looking at the processes involved, the growth of the industry, and its importance to the global economy. Along the way, we’ll explore some of the challenges and innovations that are shaping this vibrant market, offering a comprehensive overview of what makes electronic components manufacturing sales so essential in today’s tech-driven world.

What Are Electronic Components?

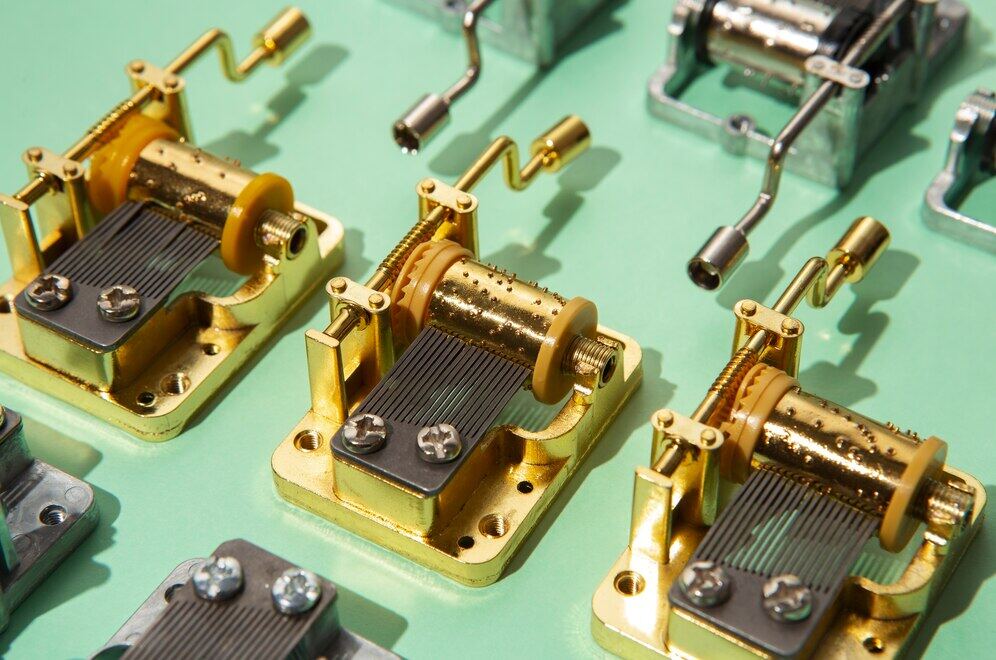

Before we dive into the industry itself, it's important to understand what electronic components are. Simply put, they are the building blocks of electronic devices. These components include resistors, capacitors, diodes, transistors, integrated circuits (ICs), connectors, and many other parts. Each component serves a unique function, from regulating current to enabling communication between different parts of a circuit. When combined, these components form the circuits that power everything from our household appliances to complex computing systems.

The electronic components manufacturing industry is responsible for creating these components in bulk, ensuring that they meet the required standards and are available for use in various electronic devices. The sales of these components are equally important, as they ensure that the right parts reach manufacturers of end-user products.

The Importance of Electronic Components in Today's World

In today’s interconnected world, almost everything we use has some form of electronic component inside it. Take a moment to look around you—chances are, you’ll spot a variety of devices powered by these components. Whether it's your smartphone, your laptop, or even your kitchen appliances, electronic components are the invisible forces that make them work.

The electronic components manufacturing sales industry has grown to meet the demand for these essential parts. Without a steady supply of these components, manufacturers would not be able to produce the cutting-edge products we rely on daily. As technologies evolve, the demand for more advanced and efficient components has only increased, driving innovation within the sector.

The Global Market for Electronic Components Manufacturing Sales

The electronic components market is vast, spanning across continents and industries. In fact, the global demand for electronic components has been on the rise for years, driven by several key factors:

The Rise of Consumer Electronics

The consumer electronics industry is one of the largest consumers of electronic components. With new gadgets being released regularly, there is a constant need for new and improved components. Smartphones, wearables, smart home devices, and gaming consoles are just a few examples of products that depend on the availability of high-quality electronic components.

Automotive Industry Transformation

The automotive industry has also seen significant growth in its reliance on electronic components. Modern cars are filled with electronics, from engine management systems to infotainment screens. As the shift toward electric vehicles (EVs) accelerates, the demand for specific components like batteries, power management systems, and sensors is skyrocketing.

Advancements in AI and IoT

Artificial intelligence (AI) and the Internet of Things (IoT) are transforming industries across the board. These technologies rely heavily on sophisticated sensors, processors, and data transmission components. As a result, the electronic components manufacturing sales sector is responding with innovations that support the development of these technologies.

5G and Communication Technologies

The rollout of 5G networks is another key driver of the electronic components market. 5G technology promises faster speeds, lower latency, and increased connectivity, all of which depend on specialized components like antennas, modulators, and semiconductors. This has led to a surge in the demand for these components, propelling the industry to new heights.

Key Players in Electronic Components Manufacturing

The electronic components manufacturing sector is home to a variety of companies, from multinational corporations to smaller, specialized firms. Some of the most well-known names in the industry include:

- Intel: Known for its microprocessors, Intel is a leader in semiconductor manufacturing, providing the heart of many computing devices.

- Samsung Electronics: In addition to smartphones, Samsung is a major player in memory chips, displays, and other electronic components.

- Texas Instruments: Specializing in analog and mixed-signal semiconductors, Texas Instruments is a key supplier for various industries, including automotive, industrial, and consumer electronics.

- Panasonic: A major supplier of capacitors, resistors, and sensors, Panasonic is a giant in the world of electronic components.

These companies, among many others, produce and sell electronic components that are essential for the development of technology. Their success relies not only on innovation but also on the efficiency and reliability of their manufacturing processes.

The Manufacturing Process: From Design to Delivery

The manufacturing of electronic components is a complex and highly precise process. It involves several stages, from the initial design of the component to its final assembly and delivery to customers. Here's a look at the key steps in the process:

Design and Prototyping

The first step in the manufacturing process is the design phase. Engineers and designers work together to create prototypes of the component, ensuring that it meets the necessary specifications and can be mass-produced efficiently. This phase also involves testing and refining the design before moving to production.

Material Sourcing

Once the design is finalized, manufacturers source the materials needed for production. These materials can range from metals like copper and gold to specialized semiconductors and plastic compounds. The quality of the materials used plays a crucial role in the performance and longevity of the final component.

Production and Assembly

After sourcing the materials, the components are produced and assembled. This stage involves intricate processes like photolithography (used to create circuits on semiconductor chips) and automated assembly lines to solder and place components onto printed circuit boards (PCBs). The assembly process is highly automated, allowing for precise and efficient production at scale.

Testing and Quality Control

Each component undergoes rigorous testing to ensure it meets quality standards. This can include electrical testing, environmental testing (to ensure the component can withstand temperature and humidity fluctuations), and reliability testing. Only components that pass these tests are sent to customers.

Packaging and Shipping

Once the components are tested and approved, they are packaged securely to prevent damage during transit. Manufacturers then ship the components to their clients, which can include large electronics companies, automotive manufacturers, or other industries that rely on these parts.

Challenges in the Electronic Components Manufacturing Sales Industry

While the electronic components manufacturing sales industry is thriving, it is not without its challenges. Some of the most notable hurdles include:

Supply Chain Disruptions

The global supply chain for electronic components is complex and vulnerable to disruptions. Events like natural disasters, trade wars, and pandemics can cause shortages in critical components, leading to delays in production and increased costs.

Technological Complexity

As technology continues to advance, the demand for more sophisticated and miniaturized components grows. This presents challenges for manufacturers, who must invest in new technologies and upgrade their production processes to keep up with changing requirements.

Price Volatility

The prices of raw materials used in the production of electronic components, such as rare earth metals and semiconductors, can fluctuate significantly. This volatility can impact the profitability of manufacturers and the pricing of end products.

Environmental Concerns

The production of electronic components often involves the use of hazardous materials, and the disposal of electronic waste is a growing environmental concern. Manufacturers are under increasing pressure to adopt more sustainable practices, both in terms of production and waste management.

The Future of Electronic Components Manufacturing Sales

Looking ahead, the electronic components manufacturing sales industry is poised for continued growth. As technology evolves, so too will the demand for innovative components. Key areas of focus for the future include:

Sustainability: The industry is increasingly focusing on sustainable manufacturing practices, including reducing waste and energy consumption. Companies are also exploring ways to recycle electronic components and reduce their environmental impact.

Miniaturization: As devices become smaller and more powerful, the need for miniaturized components will continue to grow. Manufacturers will need to develop even more advanced technologies to keep up with this demand.

Artificial Intelligence and Automation: The integration of AI and automation in the manufacturing process will continue to improve efficiency and reduce costs, allowing manufacturers to meet the growing demand for electronic components.

Conclusion

The electronic components manufacturing sales industry is a cornerstone of the modern technological landscape. It enables the production of everything from smartphones to electric vehicles, powering the innovations that shape our lives. Despite its challenges, the industry continues to thrive, driven by advances in technology and a global appetite for smarter, faster, and more efficient devices.

As we look toward the future, the industry is set to evolve even further, with sustainability, automation, and miniaturization taking center stage. The continued growth of the electronic components manufacturing sales market is a testament to the importance of these small but mighty parts in driving the technology of tomorrow. So, the next time you power on a device, remember the intricate world of electronic components that makes it all possible.